MULTI-ENTITY STOCK DEPENDENT MODEL WITH CAPACITY AND MANUFACTURE COST RESTRAINT’S

DOI:

https://doi.org/10.22452/mjs.vol43no3.5Keywords:

integrated inventory model, restricted shortages, KKT, fuzzification, variable constraintAbstract

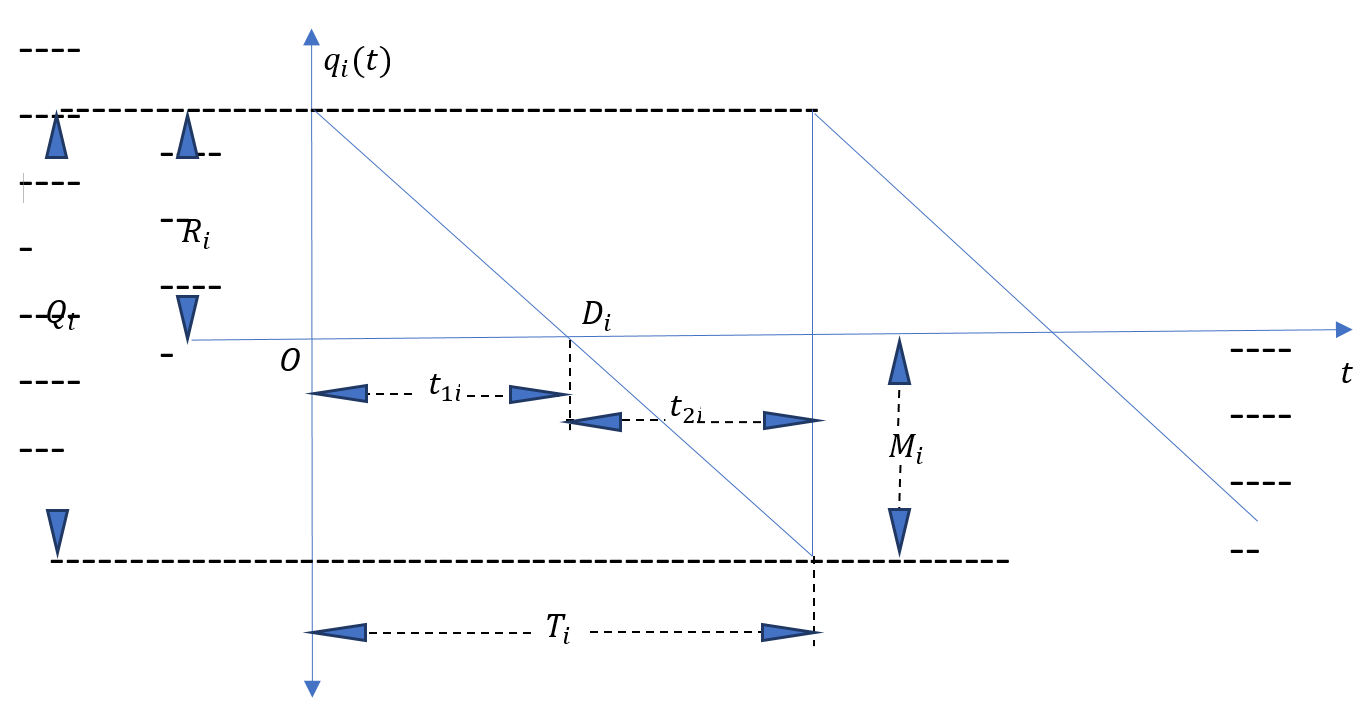

Inventory has an impact on the manufacturing process as well as supply chain operations. The fundamental goal of this research paper is to optimize the cost associated with inventories and to provide flow less continuous production process in time. Normally, demand rate of any entity in inventory control model are treated as predictable and at the same time constant too, and that the cost associated to unit inventory must be independent and non-variable in nature. Nevertheless, in practical circumstances, the unit price and demand rate of an entity may be interconnected. When the asking for an article is enormous, an entity is manufactured in huge quantities and the static charges of manufacturing being diffused over a multiple component. Henceforth, per unit article cost decreases significantly. i.e., per unit article cot and the demand of an article are related under inverse variation. So, better to consider the demand rate of an article as a variable constraint than to fixed one. In this research article, a mathematical model for multiple articles through permitted and restricted shortage and per article cost based on demand accompanied by upper and lower limits viz restricted storage space and manufacturing expenses has been constructed. Overall, investigating the simultaneous effect of storage space and manufacturing expenses in an inventory model provides valuable insights that enable cost optimization, resource allocation, capacity planning, and risk mitigation. It helps companies make informed decisions and improve their overall operational efficiency and profitability. The Multi-Entity Stock Dependent Model with Capacity and Manufacture Cost Restraints can be customized and used in a variety of sectors that include managing inventory across numerous entities and complicated supply chain networks. Here are a few examples of industries that can benefit from such a model: manufacturing industry, the retail and distributor sector, e-commerce companies, pharmaceutical and healthcare industry, automotive industry and food and beverage industry. The article cost is explored at this juncture in a fuzzy atmosphere and solutions of the model being obtained through KKT condition. Finally, a conclusion is offered in the final portion.

Downloads

References

Bardhan, S., Pal, H., &Giri, B. C. (2019). Optimal replenishment policy and preservation technology investment for a non-instantaneous deteriorating item with stock-dependent demand. Operational Research, 19(2), 347-368.

Barman, A., Das, R., & De, P. K. (2021). Optimal pricing, replenishment scheduling, and preservation technology investment policy for multi-item deteriorating inventory model under shortages. International Journal of Modeling, Simulation, and Scientific Computing, 12(05), 2150039.

Erlenkotter, D. (1990). Ford Whitman Harris and the economic order quantity model. Operations Research, 38(6), 937-946.

Hadley, G. W., & Whitten, T. (1963). TM, 1963. Analysis of Inventory systems. Englewood Cliffs, NJ, 1963.

Mashud, A. H. M., Wee, H. M., & Huang, C. V. (2021). Preservation technology investment, trade credit and partial backordering model for a non-instantaneous deteriorating inventory. RAIRO-Operations Research, 55, S51-S77.

Md. Alamin Khan, A. H. M. M., M. A. Halim. (2017). Numerous Exact Solutions Of Nonlinear Partial Differential Equations By Tan–Cot Method. Journal of Mechanics of Continua Mathematical sciences, 11(2), 37-48.

Md Mashud, A. H., Pervin, M., Mishra, U., Daryanto, Y., Tseng, M.-L., & Lim, M. K. (2021). A sustainable inventory model with controllable carbon emissions in green-warehouse farms. Journal of Cleaner Production, 298, 126777. doi:https://doi.org/10.1016/j.jclepro.2021.126777

Miah, M. S., Islam, M. M., Hasan, M., Mashud, A. H. M., Roy, D., & Sana, S. S. (2021). A Discount Technique-Based Inventory Management on Electronics Products Supply Chain. Journal of Risk and Financial Management, 14(9), 398.

Mishra, V. K. (2014). Controllable deterioration rate for time-dependent demand and time-varying holding cost. Yugoslav Journal of Operations Research, 24(1), 87-98.

Mishra, U., Mashud, A. H. M., Tseng, M.-L., & Wu, J.-Z. (2021). Optimizing a Sustainable Supply Chain Inventory Model for Controllable Deterioration and Emission Rates in a Greenhouse Farm. Mathematics, 9(5), 495.

Nath, B. K., & Sen, N. (2021). A partially backlogged two-warehouse EOQ model with non-instantaneous deteriorating items, price and time dependent demand and preservation technology using interval number. International Journal of Mathematics in Operational Research, 20(2), 149-181.

Pal, H., Bardhan, S., &Giri, B. C. (2018). Optimal replenishment policy for non-instantaneously perishable items with preservation technology and random deterioration start time. International Journal of Management Science and Engineering Management, 13(3), 188-199.

Rahman, M. M., Ahmed, R., Mashud, A. H. M., Malik, A. I., Miah, S., & Abedin, M. Z. (2022). Consumption-Based CO2 Emissions on Sustainable Development Goals of SAARC Region. Sustainibility, 14(3), 1467.

Rahman, M. M., Anan, N., Mashud, A. H. M., Hasan, M., & Tseng, M.-L. (2022). Consumption-based CO2 emissions accounting and scenario simulation in Asia and the Pacific region. Environmental Science and Pollution Research, 29(23), 34607-34623. doi:10.1007/s11356-021-18265-w

Roy, D., Hasan, S. M. M., Rashid, M. M., Hezam, I. M., Al-Amin, M., Chandra Roy, T., . . . Mashud, A. H. M. (2022). A Sustainable Advance Payment Scheme for Deteriorating Items with Preservation Technology. Processes, 10(3), 546.

Roy, D., &Mashud, A. H. M. (2022). Optimizing profit in a controlled environment: Assessing the synergy between preservation technology and cap-and-trade policy. Journal of King Saud University - Science, 34(3), 101899. doi:https://doi.org/10.1016/j.jksus.2022.101899

Shaikh, A. A., Mashud, A. H. M., Uddin, M. S., & Khan, M. A.-A. (2017). Non-instantaneous deterioration inventory model with price and stock dependent demand for fully backlogged shortages under inflation. International Journal of Business Forecasting and Marketing Intelligence, 3(2), 152-164.

Shaikh, A. A., Panda, G. C., Khan, M. A.-A., Mashud, A. H. M., & Biswas, A. (2020). An inventory model for deteriorating items with preservation facility of ramp type demand and trade credit. Int. J. Math. Oper. Res., 17(4), 514-551.

Silver, E. A., & Peterson, R. (1985). Decision systems for inventory management and production planning (Vol. 18). Wiley.

Sultana, S., Mashud, A. H. M., Daryanto, Y., Miah, S., Alrasheedi, A., &Hezam, I. M. (2022). The Role of the Discount Policy of Prepayment on Environmentally Friendly Inventory Management. Fractal and Fractional, 6(1), 26.

Yang, H. L., & Chang, C. T. (2013). A two-warehouse partial backlogging inventory model for deteriorating items with permissible delay in payment under inflation. Applied Mathematical Modelling, 37(5), 2717-2726.

Zia, N. P., &Taleizadeh, A. A. (2015). A lot-sizing model with backordering under hybrid linked-to-order multiple advance payments and delayed payment. Transportation Research Part E: Logistics and Transportation Review, 82, 19-37.

Downloads

Published

How to Cite

Issue

Section

License

Transfer of Copyrights

- In the event of publication of the manuscript entitled [INSERT MANUSCRIPT TITLE AND REF NO.] in the Malaysian Journal of Science, I hereby transfer copyrights of the manuscript title, abstract and contents to the Malaysian Journal of Science and the Faculty of Science, University of Malaya (as the publisher) for the full legal term of copyright and any renewals thereof throughout the world in any format, and any media for communication.

Conditions of Publication

- I hereby state that this manuscript to be published is an original work, unpublished in any form prior and I have obtained the necessary permission for the reproduction (or am the owner) of any images, illustrations, tables, charts, figures, maps, photographs and other visual materials of whom the copyrights is owned by a third party.

- This manuscript contains no statements that are contradictory to the relevant local and international laws or that infringes on the rights of others.

- I agree to indemnify the Malaysian Journal of Science and the Faculty of Science, University of Malaya (as the publisher) in the event of any claims that arise in regards to the above conditions and assume full liability on the published manuscript.

Reviewer’s Responsibilities

- Reviewers must treat the manuscripts received for reviewing process as confidential. It must not be shown or discussed with others without the authorization from the editor of MJS.

- Reviewers assigned must not have conflicts of interest with respect to the original work, the authors of the article or the research funding.

- Reviewers should judge or evaluate the manuscripts objective as possible. The feedback from the reviewers should be express clearly with supporting arguments.

- If the assigned reviewer considers themselves not able to complete the review of the manuscript, they must communicate with the editor, so that the manuscript could be sent to another suitable reviewer.

Copyright: Rights of the Author(s)

- Effective 2007, it will become the policy of the Malaysian Journal of Science (published by the Faculty of Science, University of Malaya) to obtain copyrights of all manuscripts published. This is to facilitate:

- Protection against copyright infringement of the manuscript through copyright breaches or piracy.

- Timely handling of reproduction requests from authorized third parties that are addressed directly to the Faculty of Science, University of Malaya.

- As the author, you may publish the fore-mentioned manuscript, whole or any part thereof, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given. You may produce copies of your manuscript, whole or any part thereof, for teaching purposes or to be provided, on individual basis, to fellow researchers.

- You may include the fore-mentioned manuscript, whole or any part thereof, electronically on a secure network at your affiliated institution, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given.

- You may include the fore-mentioned manuscript, whole or any part thereof, on the World Wide Web, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given.

- In the event that your manuscript, whole or any part thereof, has been requested to be reproduced, for any purpose or in any form approved by the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers), you will be informed. It is requested that any changes to your contact details (especially e-mail addresses) are made known.

Copyright: Role and responsibility of the Author(s)

- In the event of the manuscript to be published in the Malaysian Journal of Science contains materials copyrighted to others prior, it is the responsibility of current author(s) to obtain written permission from the copyright owner or owners.

- This written permission should be submitted with the proof-copy of the manuscript to be published in the Malaysian Journal of Science

Licensing Policy

Malaysian Journal of Science is an open-access journal that follows the Creative Commons Attribution-Non-commercial 4.0 International License (CC BY-NC 4.0)

CC BY – NC 4.0: Under this licence, the reusers to distribute, remix, alter, and build upon the content in any media or format for non-commercial purposes only, as long as proper acknowledgement is given to the authors of the original work. Please take the time to read the whole licence agreement (https://creativecommons.org/licenses/by-nc/4.0/legalcode ).